Star Wars Prop - Base Hacker System - Post Hand In Upgrades

Communication Tower Upgrade - Comm Tower Base Stiffening and Stabilisation

Strengthening the Communication Tower Base Stability Issues:

History

When I created the towers, they were done simply by gluing components together and thus was rubbish that fell apart.

No spine and all parts glued on top of the Dyson motors on top of the wing box ends.

To add a spine and root it deep inside through the Dyson motors and into the wing box end below this was drilled though with long bits.

The Problems After Adding Spine - Wobbly Base

The inside of the Dyson motors and wind box cavities below were all hollow, so not much to hold the shaft, more so the end which could wobble around and pivoted in the Nerf disk on top of the Dyson motors creating a stress point in fragile material.

None of this was solid. The entry point of the thread bar in components acted like a pivot made from very weak breakable Nerf Polystyrene parts.

The Dyson Motors themselves had problems staying stuck to the main body. As the towers wobble or were pressurised to the side with sheer forcessuch as laying in the crate this unstuck the bas of the Dysons motors so it was just the shaft holding them in place.

The Problems After Adding Spine - Wobbly Base

The inside of the Dyson motors and wind box cavities below were all hollow, so not much to hold the shaft, more so the end which could wobble around and pivoted in the Nerf disk on top of the Dyson motors creating a stress point in fragile material.

None of this was solid. The entry point of the thread bar in components acted like a pivot made from very weak breakable Nerf Polystyrene parts.

The Dyson Motors themselves had problems staying stuck to the main body. As the towers wobble or were pressurised to the side with sheer forces such as laying in the crate this unstuck the base of the Dysons motors so it was just the shaft holding them in place.

Loose Parts Falling Off

Various kit bash parts kept falling off as only glued on. The cylinders as the top often as handled they were held to twist the communication towers rubbing them off and the the up pointing gun like parts on the nerf disk

Strengthening the Tower Base Stability Solutions:

Strengthening the Tower Base Problem Solving Technique 1 :

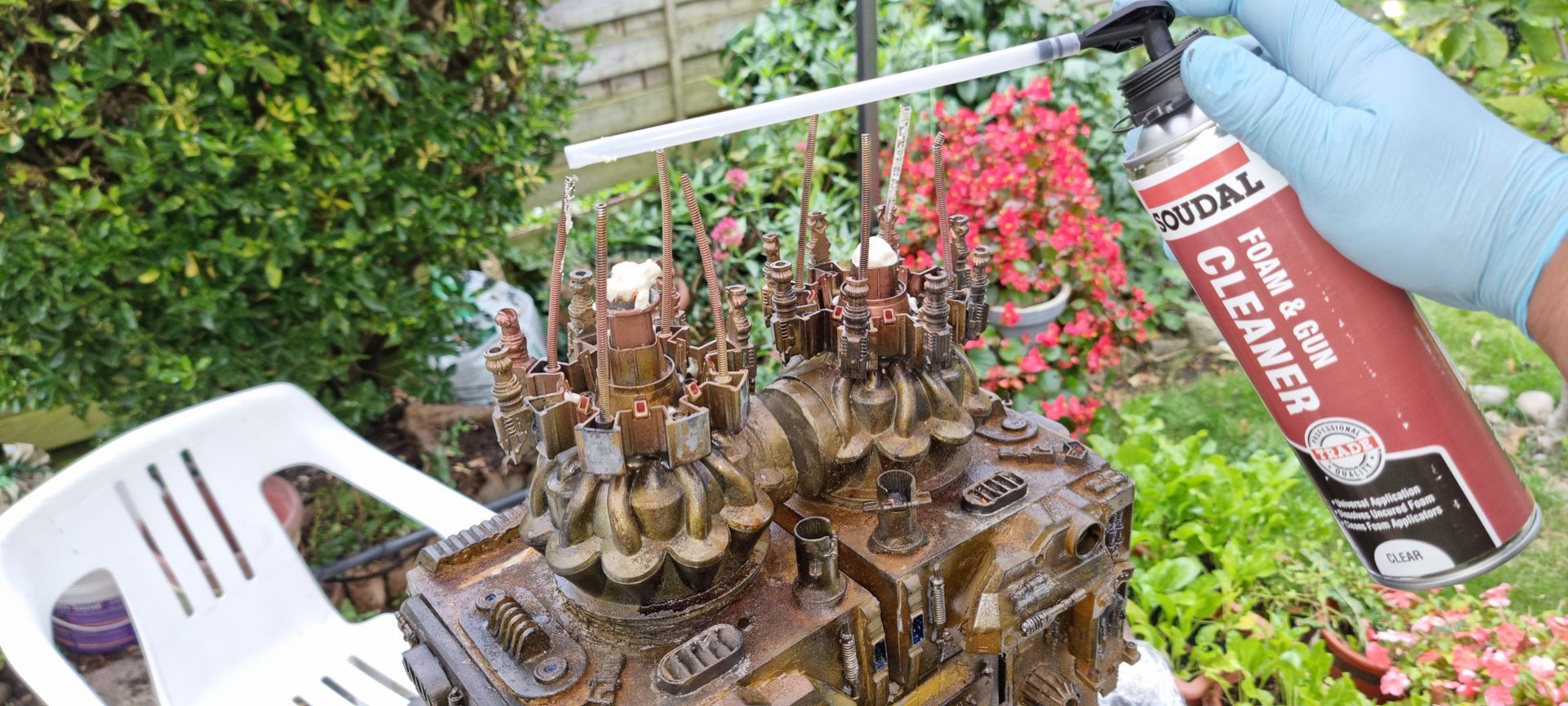

Movement Preventing Cavity Foam Filling

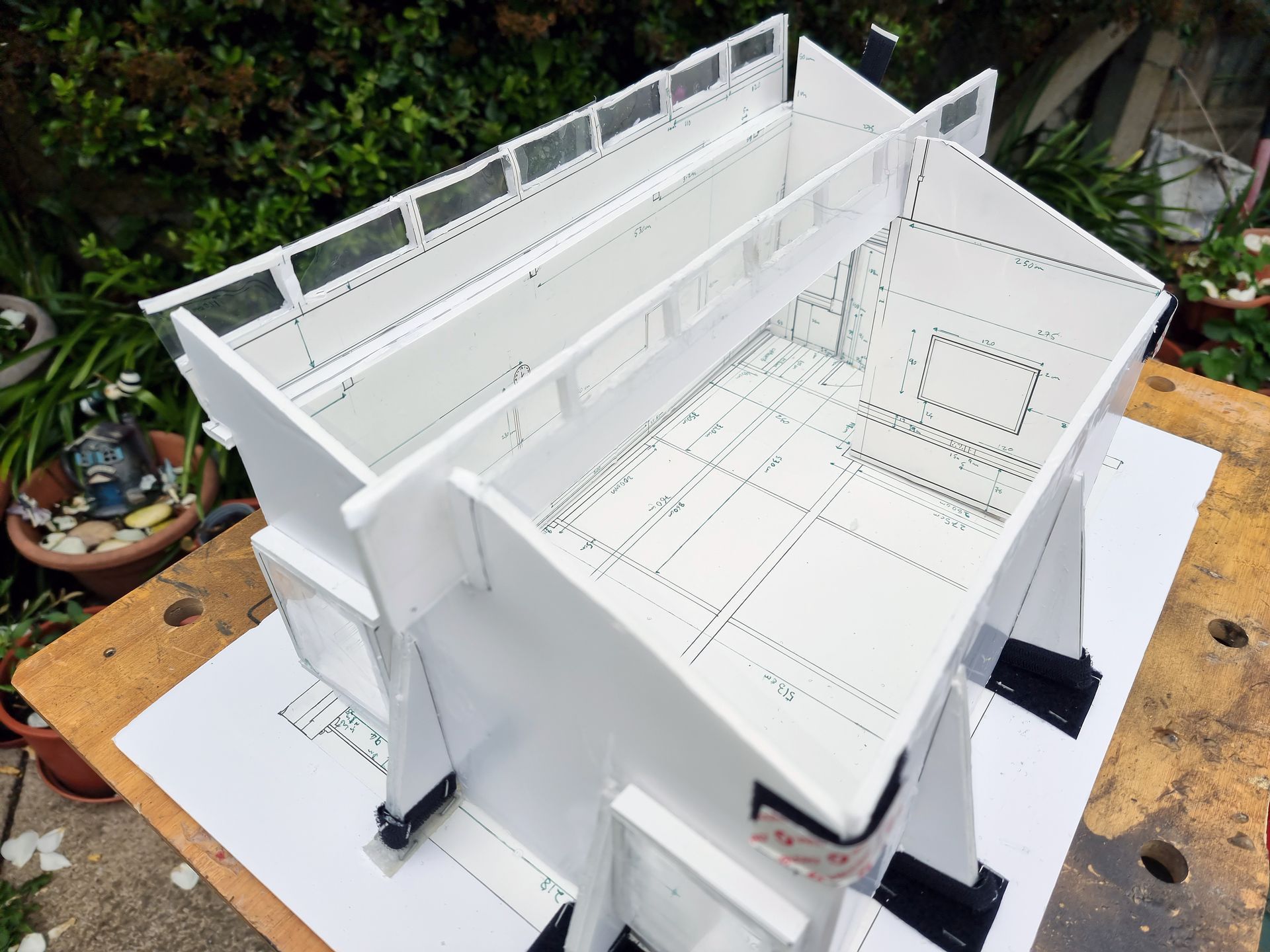

The base for the towers needed strengthening to create a strong foundation and two methods were used here.

The problem was that the connection parts above the Dyson motors and the wing boxed ends.

- To increase the length of the thread bars mentioned above to go deep inside into the wing boxes.

- As this was a retrofit, I had no intension to cut open the boxes or Dyson Motors. This would probably wreck things.

- To create a firmer hold by stuffing the end of wing empty boxes and hollow caverns of Dyson motors.

i thought fill with some sort of expanding materials to fill the gaps. - I tried to do this with expanding insulation foam from a can.

- Whilst the foam was not very had when set it would be firem enough to stop the shafts wobbling all over the place and make for a firmer base.

Weak Communication Transmitters Problem Solving - 2

Kit Bash Connection Component Strengthening & Backups

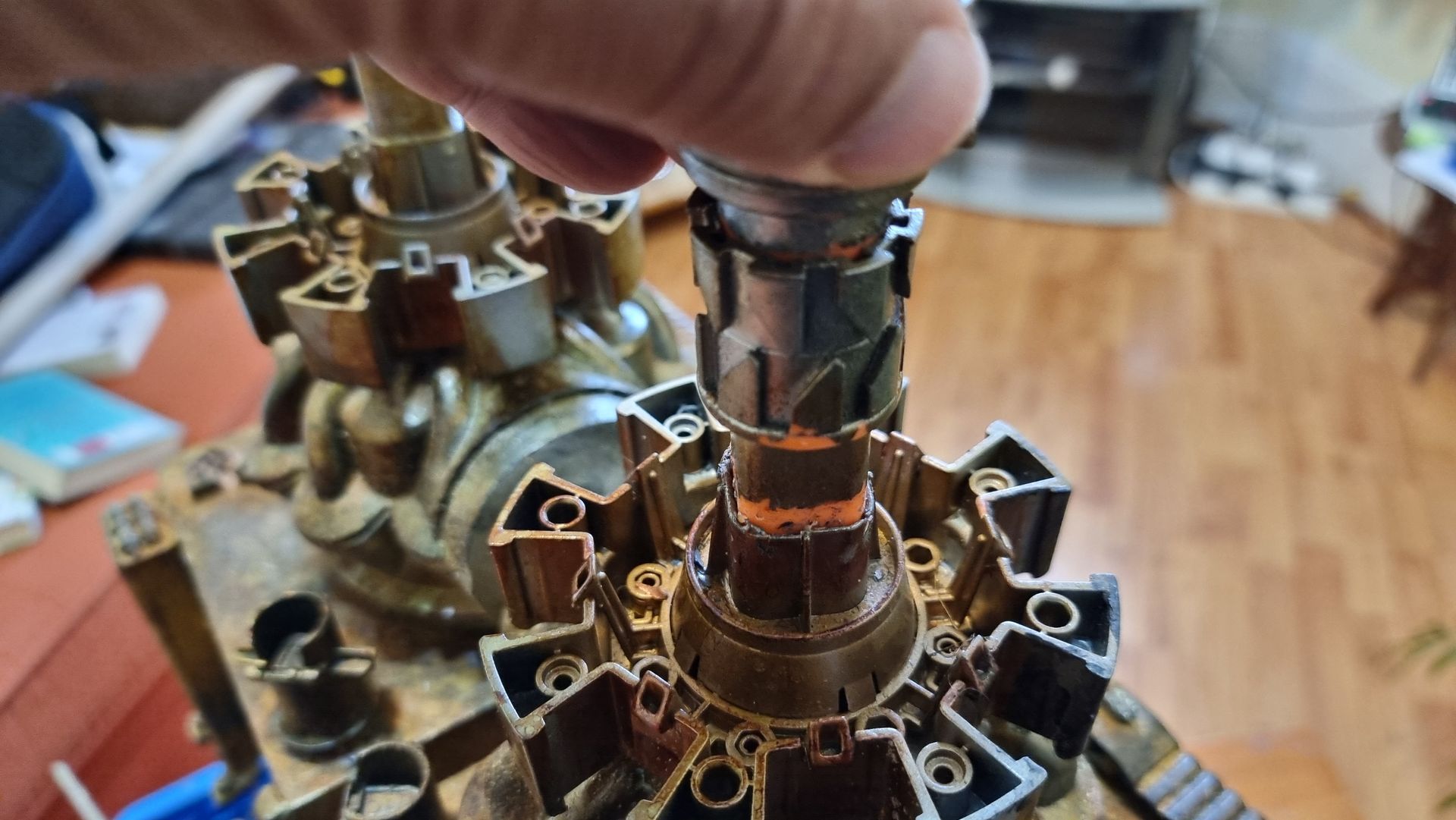

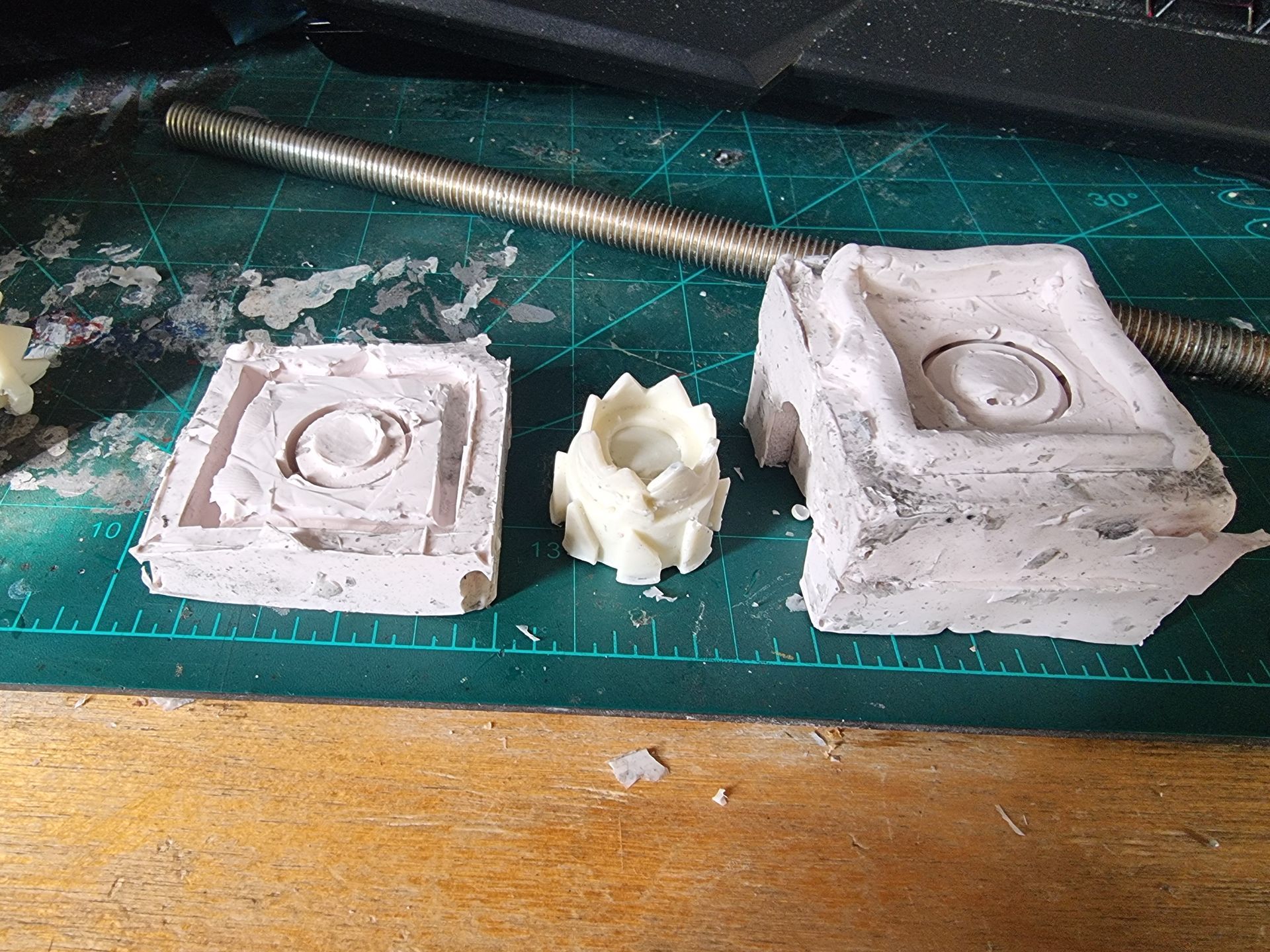

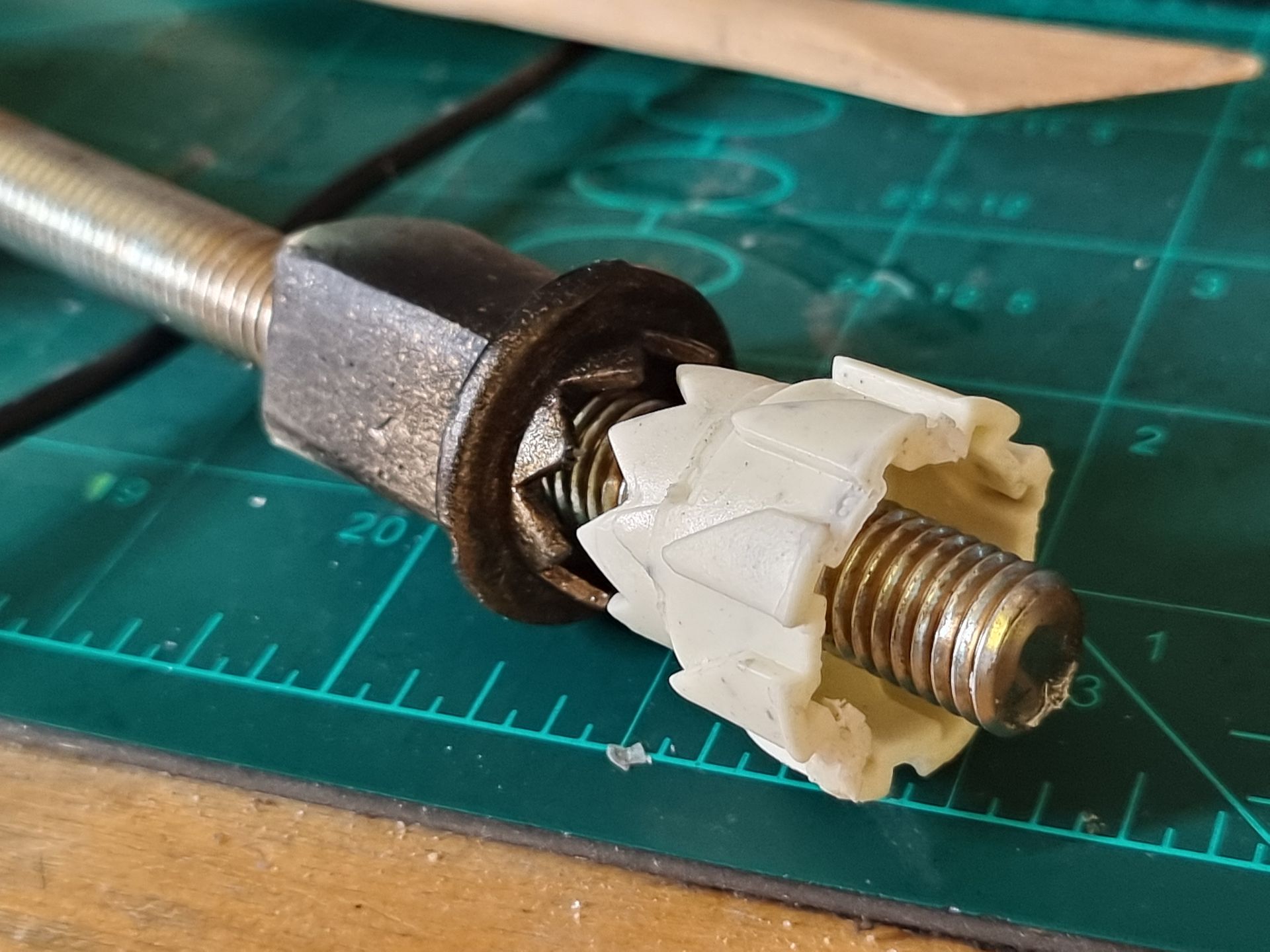

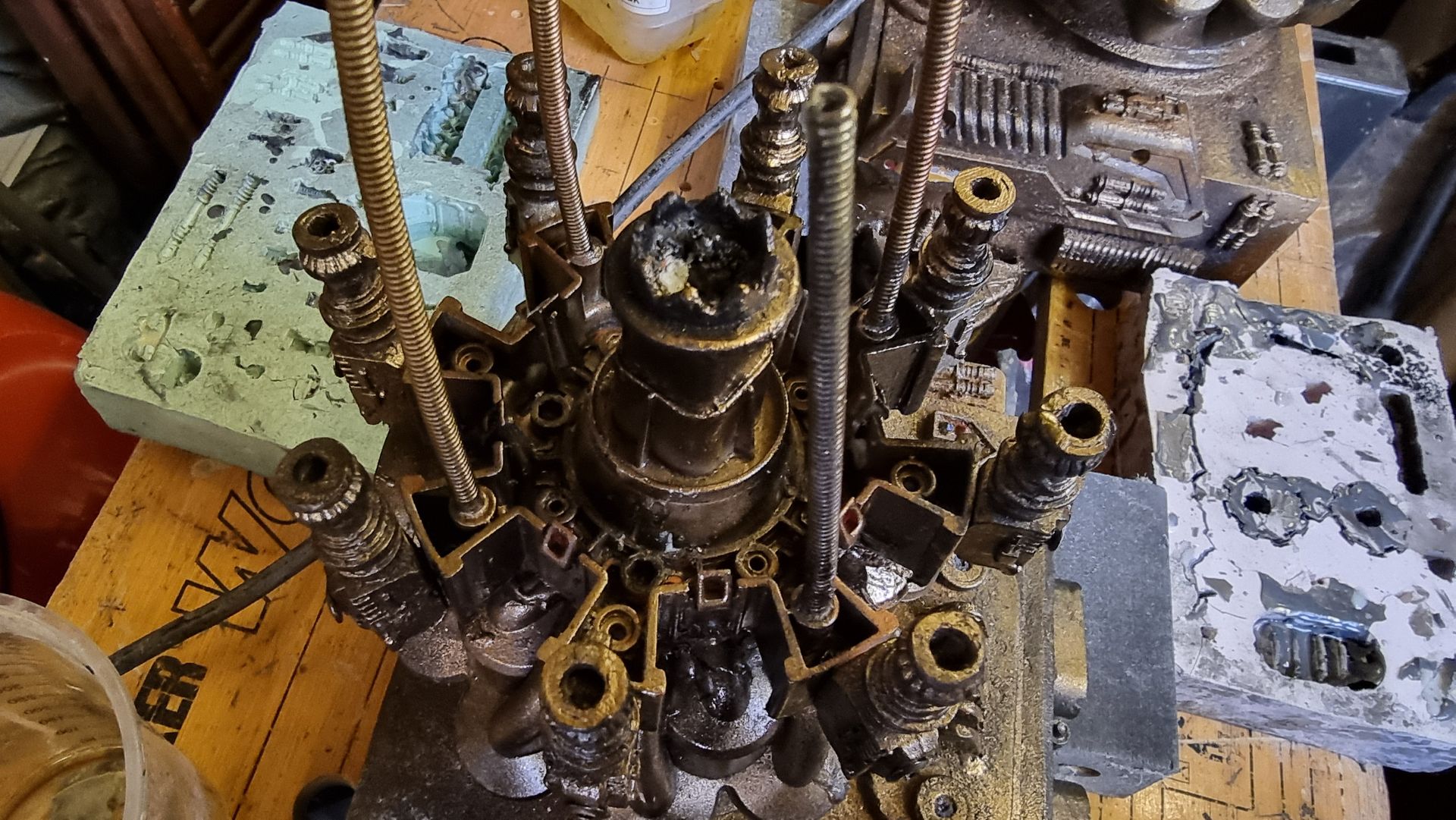

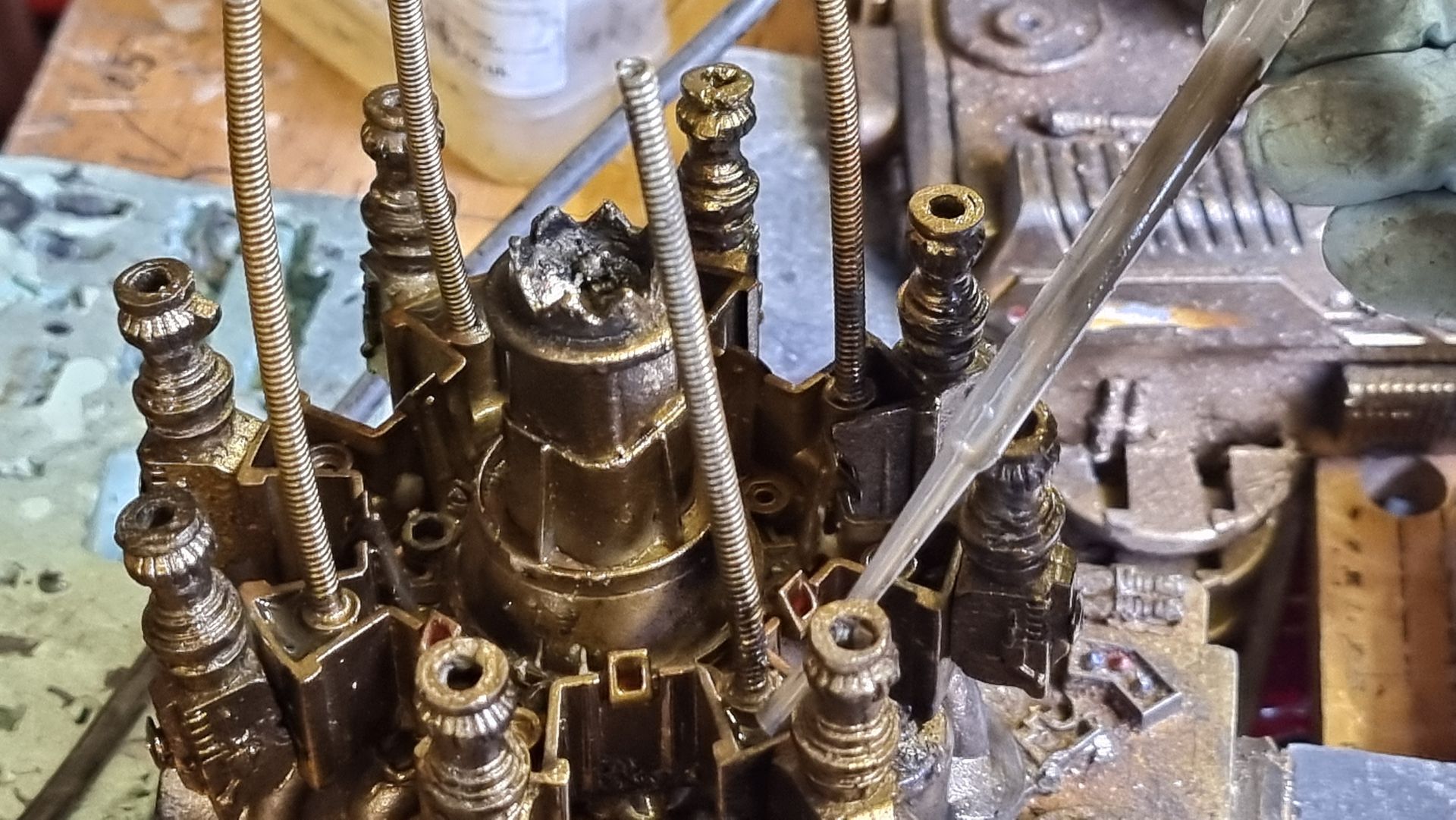

Just above the Dyson motors was a set of interlocking connection parts taken from Nerf guns. Given these were places at a key stress point and could not be replaced as from certain Nerf gun parts, that had been purchased from Ebay, second hand, and were most likely discontinued it seemed wise to make moulds so replacement and spares could be made.

I also could see these parts where fragile and the long square part with the crown to the right here was where the spike entered and at the most stressed point. Being hollow it was also not holding the shaft, so I tried to make a new mould that filled in the inside to make a solid part from my resin. This I could then drill through and add a taped interior screw thread.

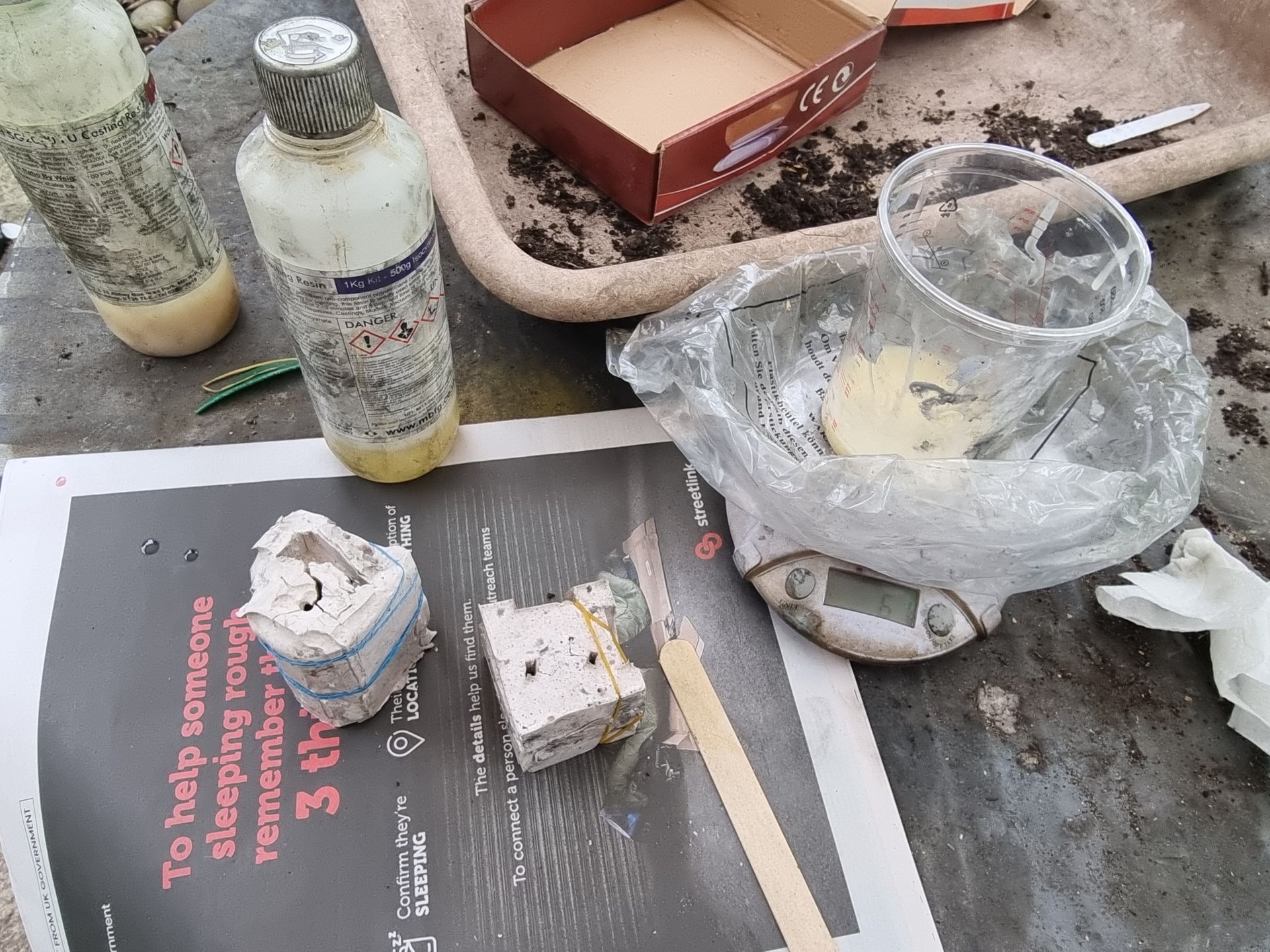

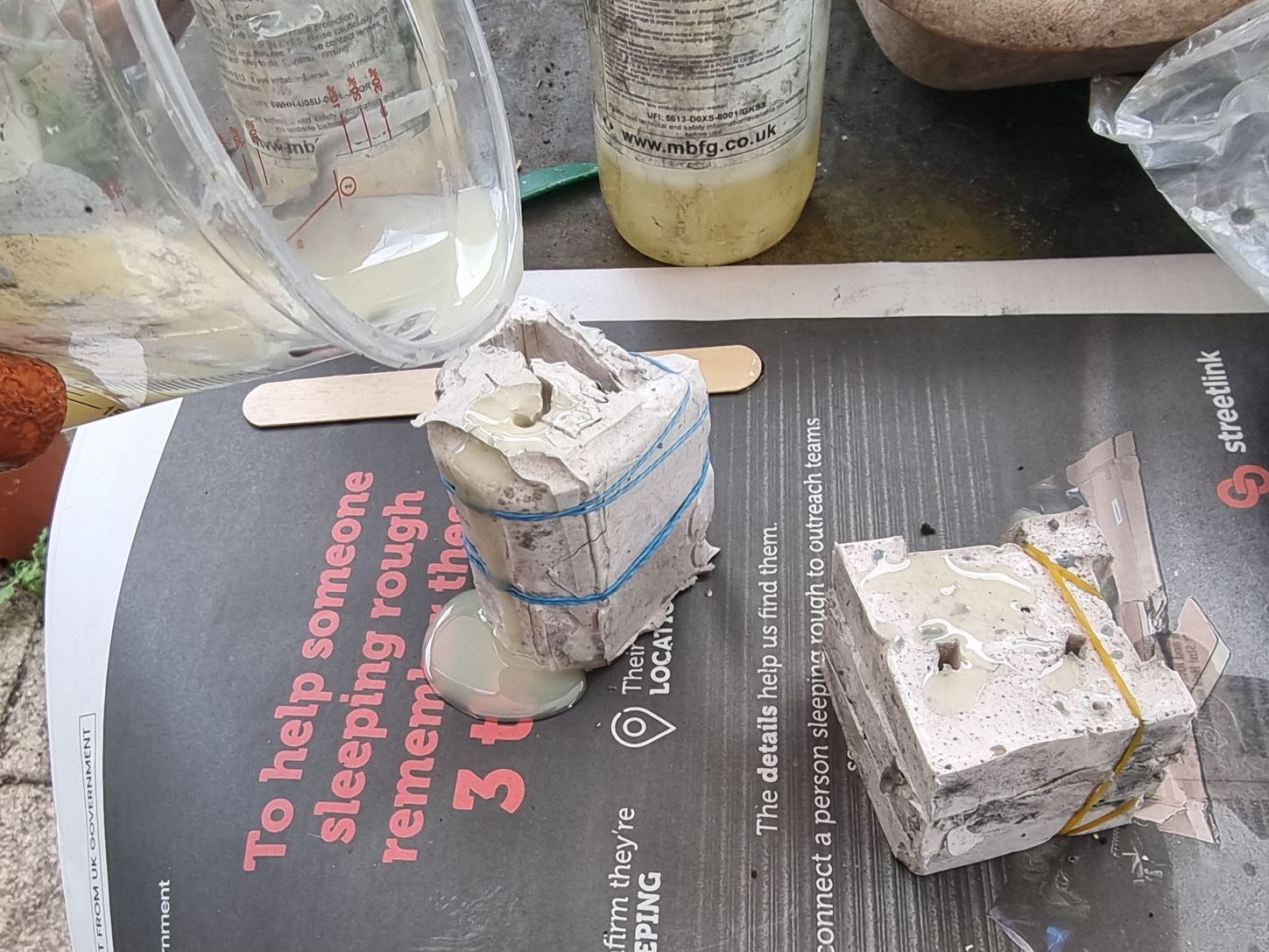

As these were complex fully 3D shapes with overhangs and internal cavities 2-part moulds were required. Plastaline was used to mask off the lower halves of the mould making blocks, whilst the first part of the moulds was filled with silicon and when set quick release was spray was applied before filling the second half with silicon.

These could then be filled with fast cast resin.

I incorporated a hole punch indent to help drilling in the design of the parts

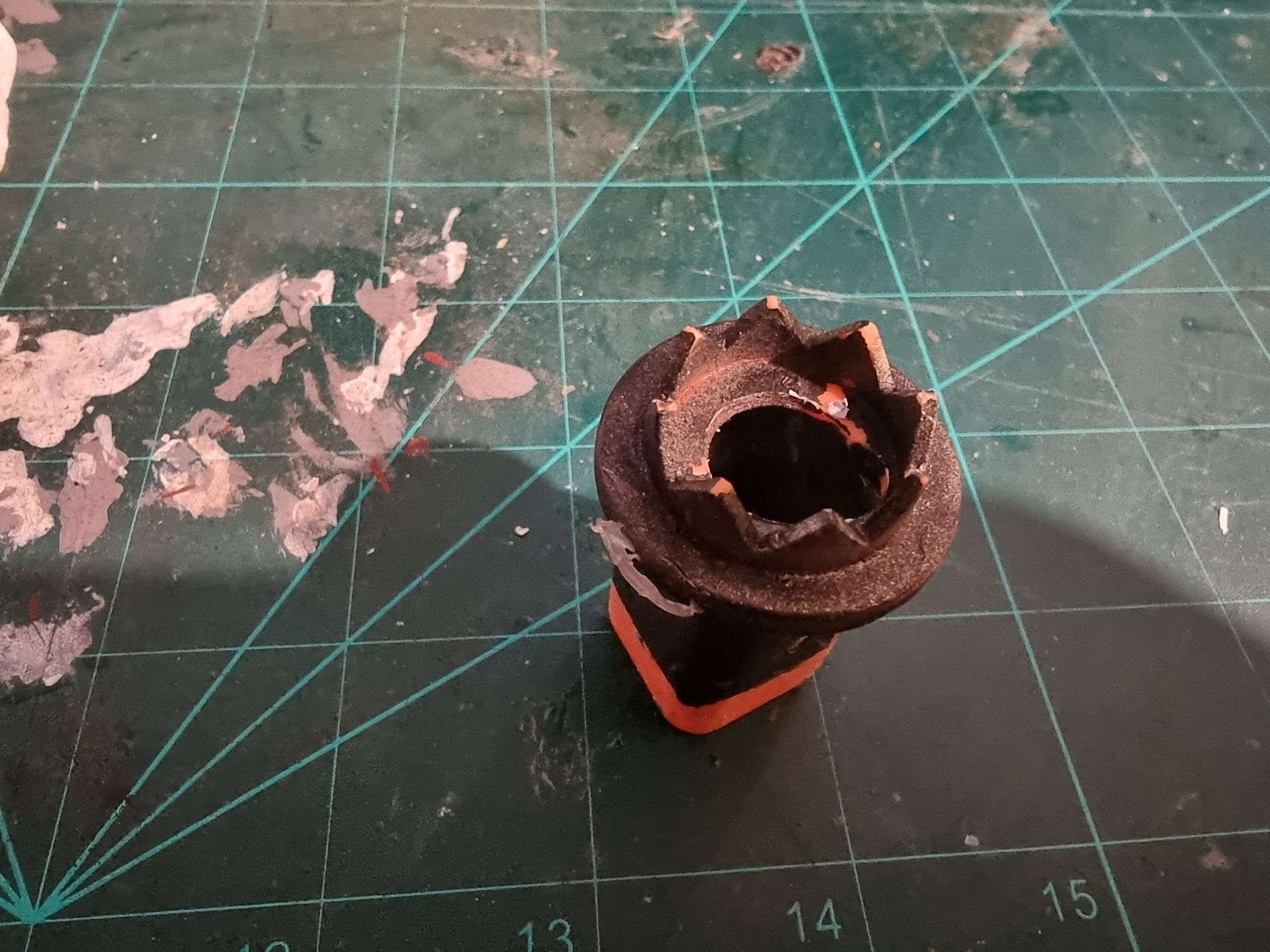

Weak Communication Transmitters Problem Solving 3 - Resin Fill Plug Reinforcement

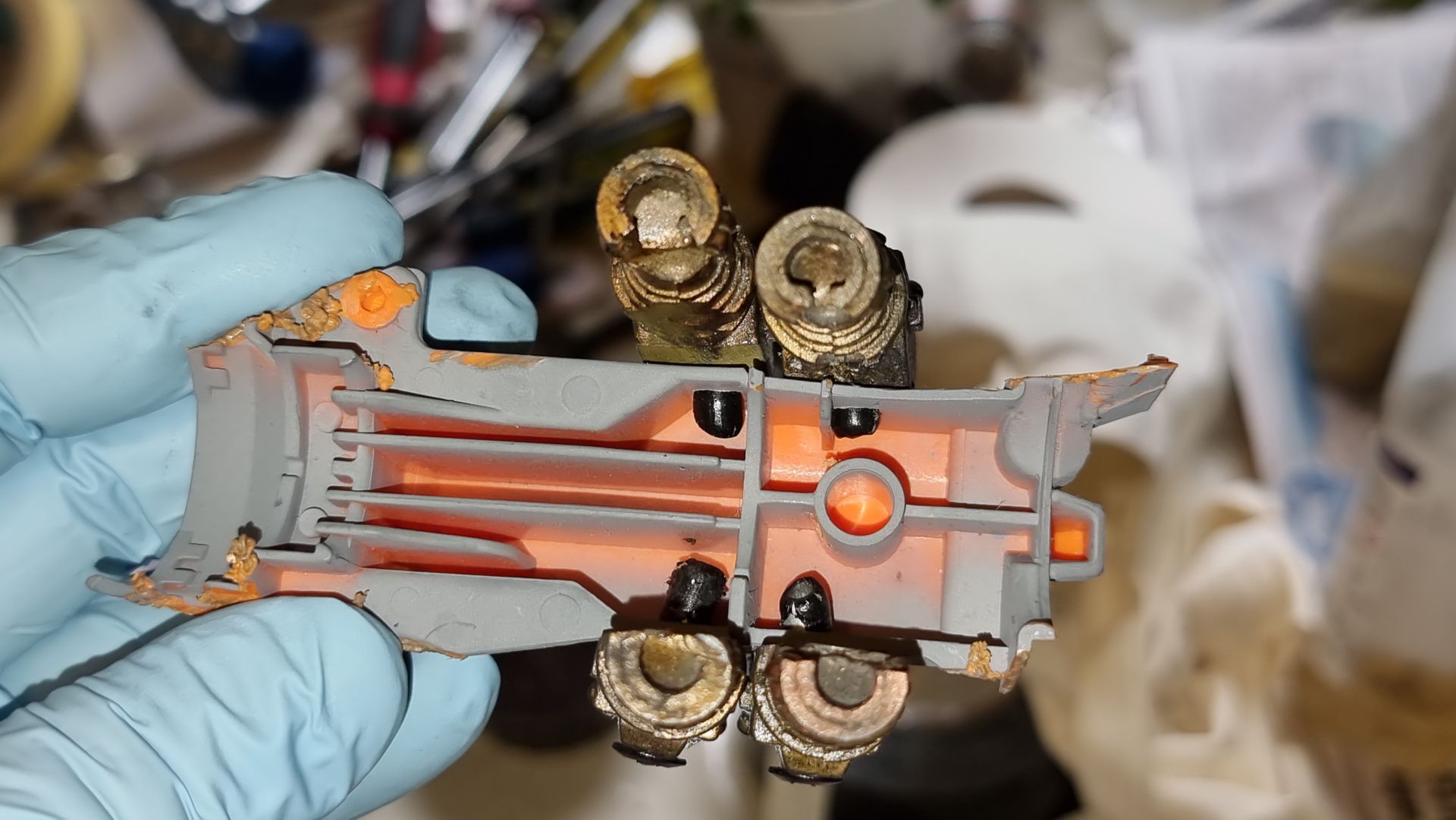

However nervous that the upward pointing kit bash gun parts were only held by 1mm or ABS from a nerf gun Cartridge I came up with the idea of filling the compartment where the rivet had gone through with resin. I also looked at use of Epoxy.

That way the part the rivet as watched had the head immersed in hard resin and not just thin plastic do less likely to snap off a chuck of the disc if caught on something.

As well as being much stronger the load was spread over the whole disc.

I tested the theory first with an orange prototype to see if it would work.

This also solidified the support cables bond with the disc.

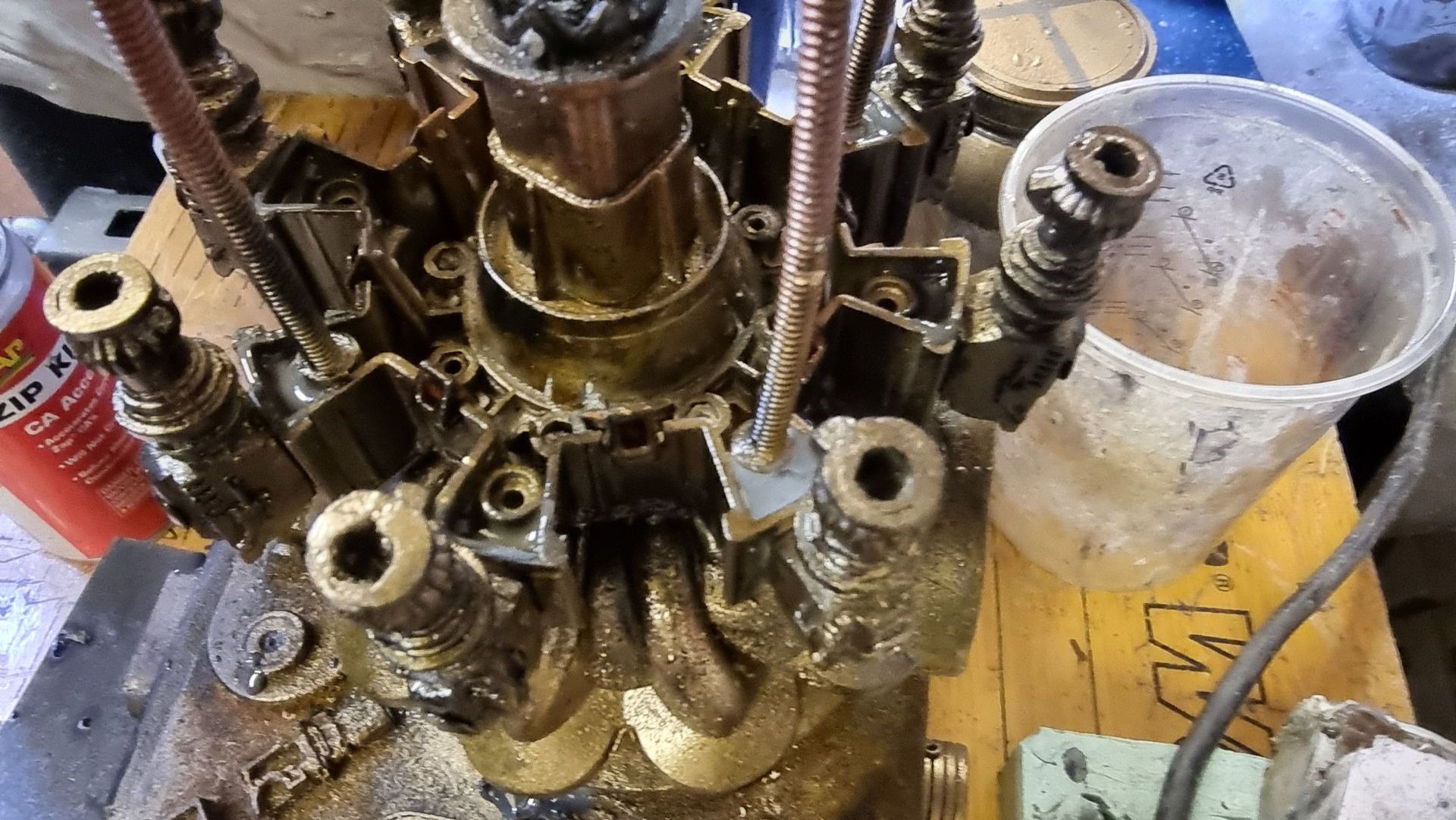

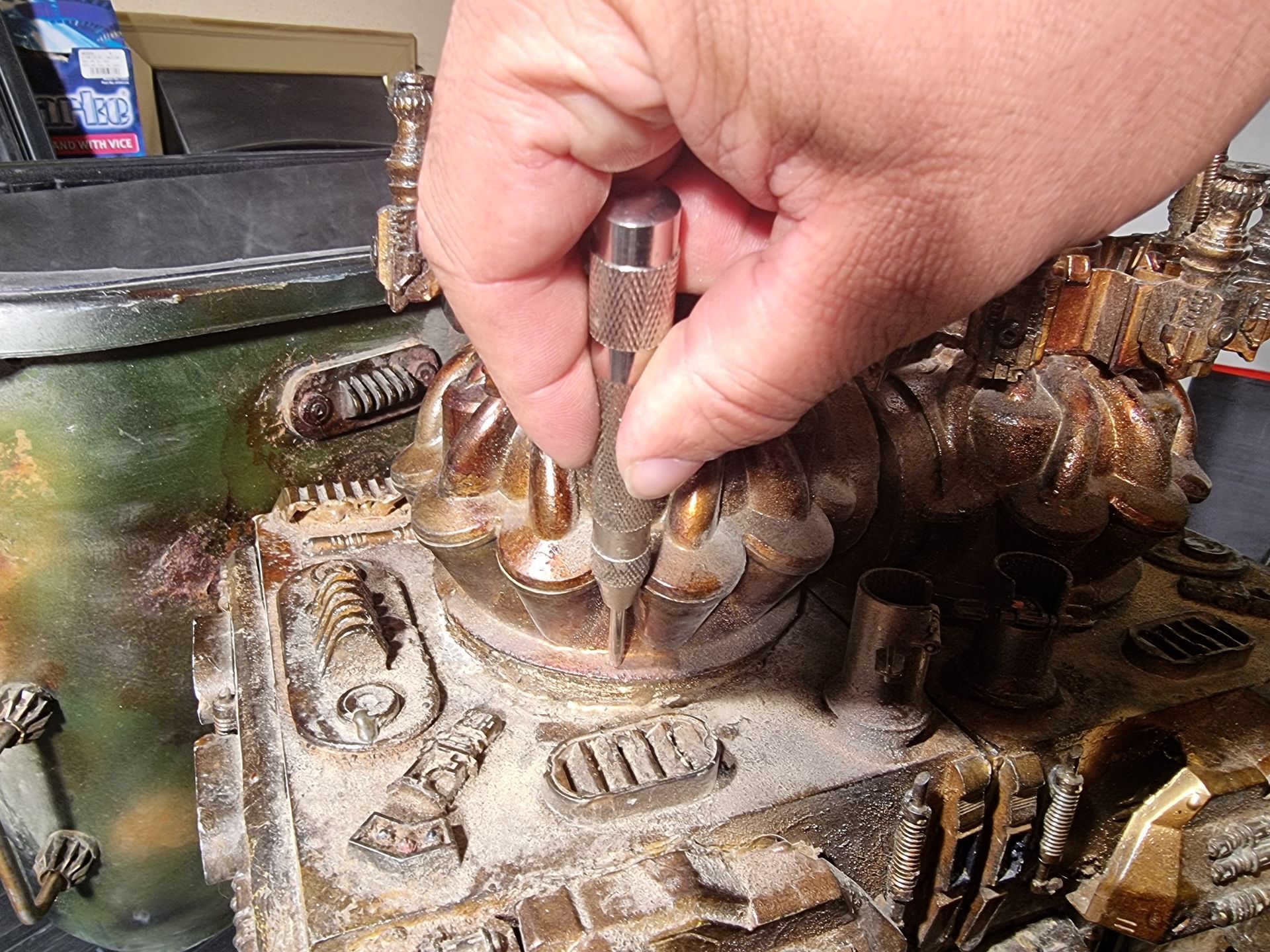

Weak Communication Transmitters Problem Solving 4 - Riveting on the Dyson Motors

What was found when using the Tower prop with the transport case the communication towers were loosened to wobble with the Dyson motors detaching from the tower body box ends so it’s only the shaft holding things together.

I tried adding a layer of foam to give some flex and various glues but nothing lasted. I have how inserted rivets around the base of the Dyson motors with holes at roughly a 45 degree down.

These were spray painted to blend in.

I found I needed at least 40mm rivets to get through the layers and at an angle.

I also had the problem of the drill head damaging the Dyson moters bumping in whilst spinning as the drill bits broke through.

This I just painted over and it adds to the wear and tear look.