Star Wars Prop - Base Hacker - Transport Case

Lid Structure Strenghtening

Lid Structure Problem Solving

As mentioned, the lid was flexible and this become known when I found the spray paint was flaking and pealing off in significant amounts. This would not be a problem if the lid was metallic, but all that was exposes was black plastic not rust patches.

This was a particular problem with concave sections such as indents for wheels and in the hexagon pattern indents as well as the groves.

Problem Solution 2: Lid Structure Problem Solving

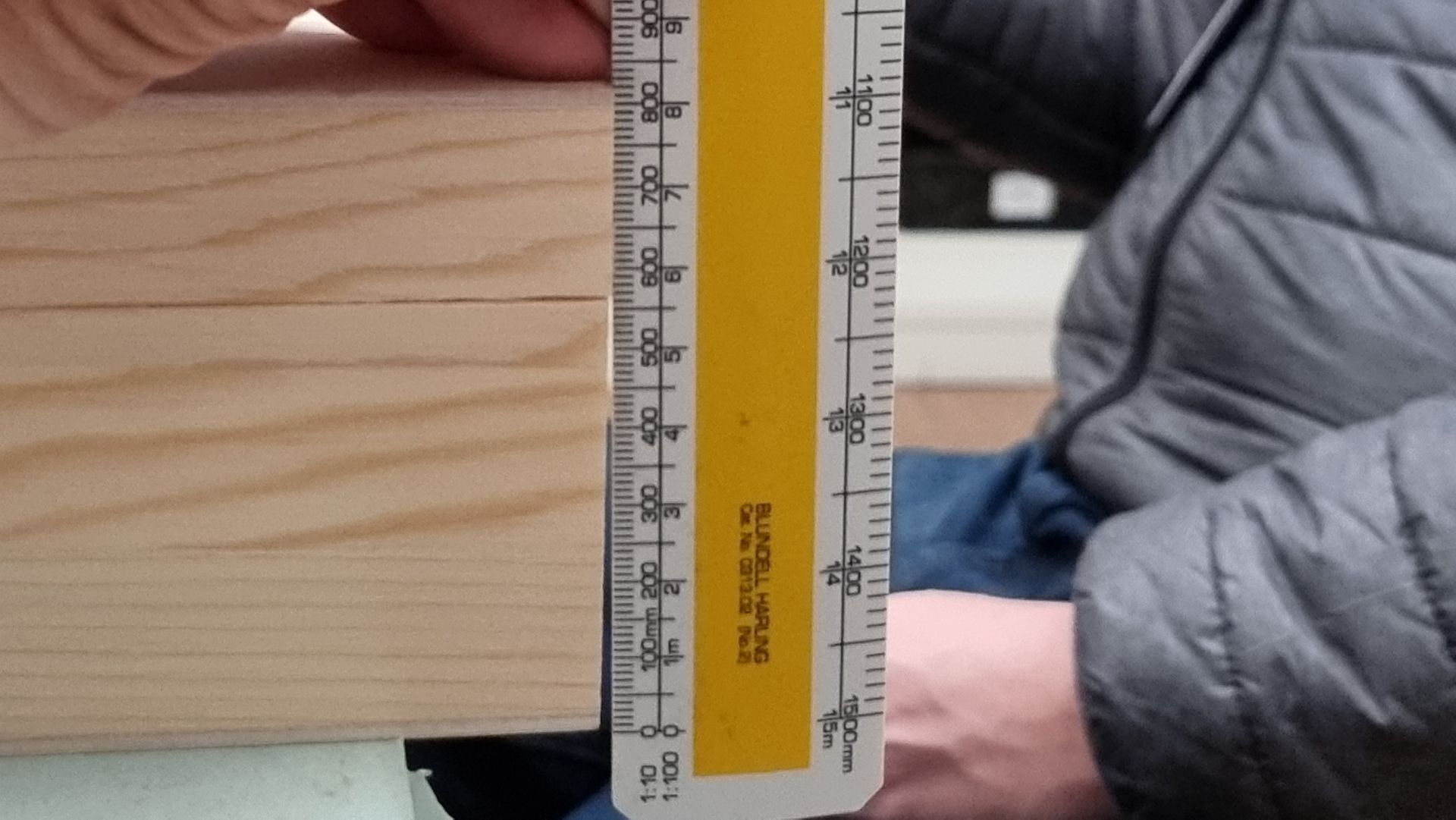

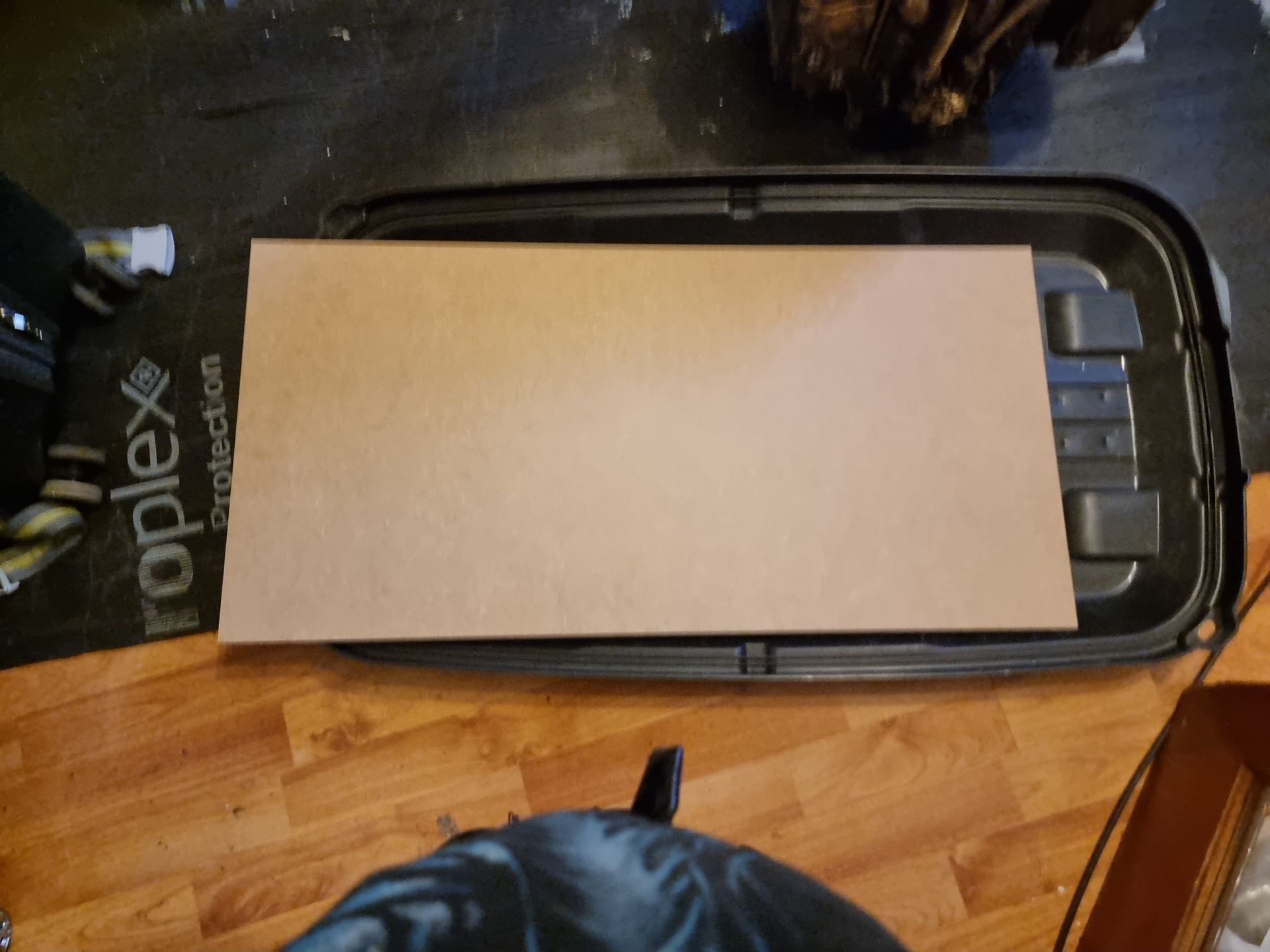

My solution was to rivet a board under the lid surface to stiffen it. MDF was found to be stuffer at the 5 - 6 mm thickness than plywood, so this was used and the underside painted black.

My mitre saw and multitool was used to cut the board and I used a milling drill bit to curve the internal corners to prevent structural weak points.

A protective layer of Plastzote foam was held in place with velcro on the underside to protect the prop both from the hard lid and the extruded rivet ends.