Star Wars Prop - Base Hacker System - Post Hand in Upgrades

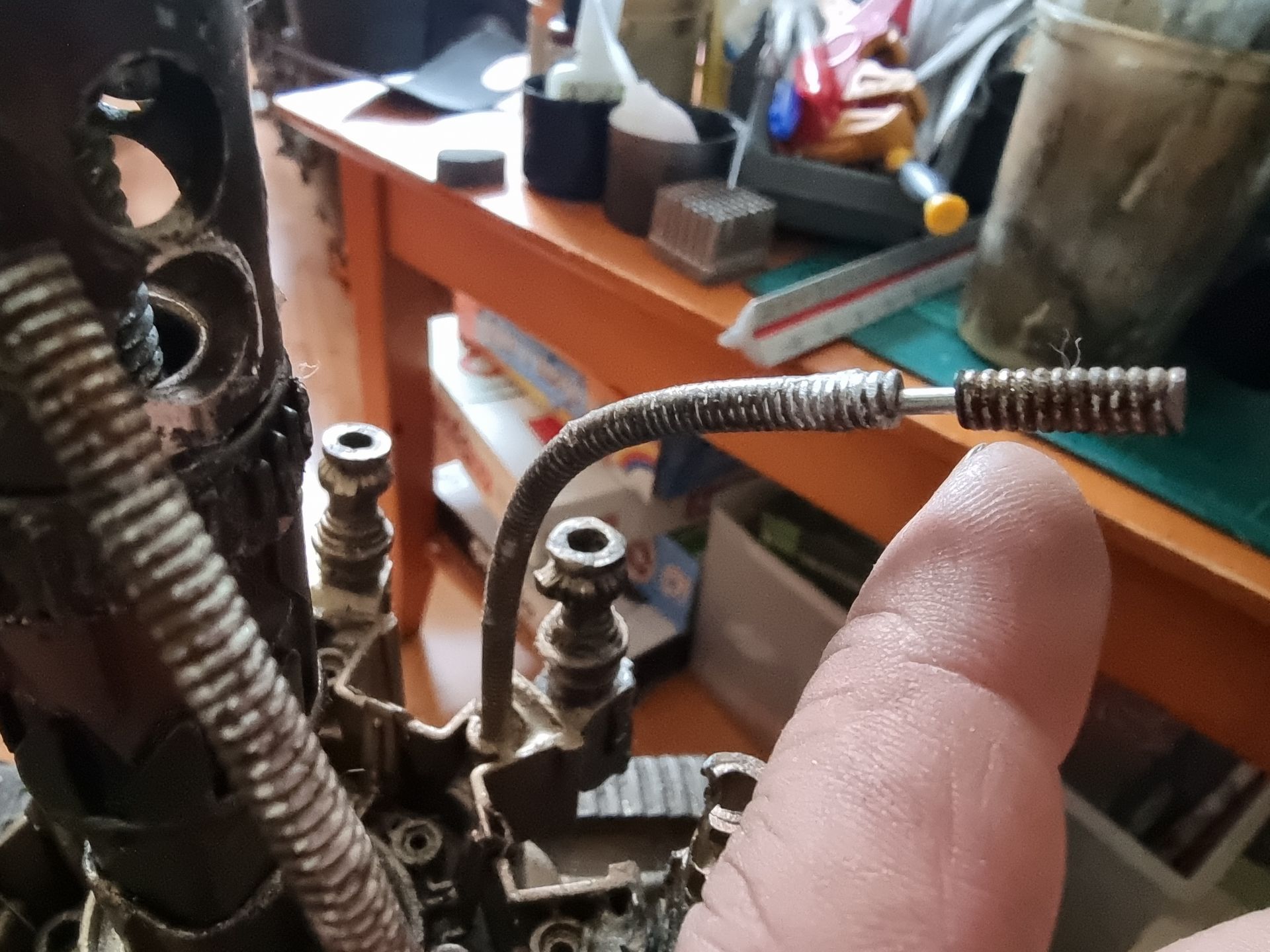

Communication Tower Upgrade - Adding, Lenghtening and Reinforcing Cable Supports

Support Cable Development and Problem Solving

I wanted to add kit bashing that looked technical like pipes or hoses and found support cables that were made from drain cleaning springs could work well.

Whilst the cables need to be locked into Nerf Disc base, the top ends need to be detachable so the towers can turn to unscrew to separate from the prop if need be.

Adding the Support Cables Cutting Issues

At first cutting and adding these spring cables made from drain clearing tools looked like it would be easy but turned out these were a total pain as due to their springing, flexible tendency to vibrate nature they were all but impossible to cut.

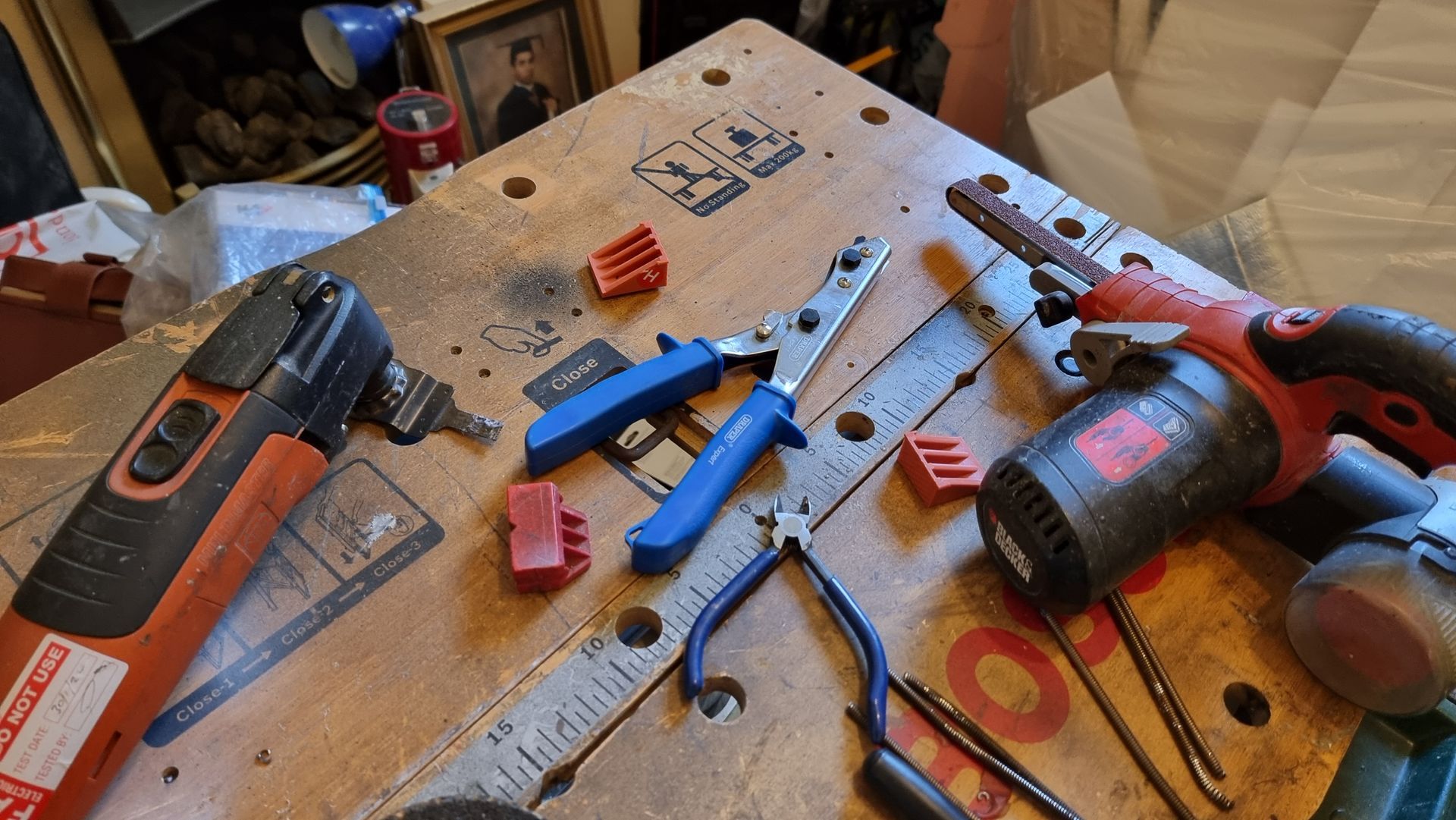

Tools that failed included my:

- Mitre Saw

- Wire Cutters

- Nibler Tool

- Jig Saw

- Various attachments on my Finn Multi tool

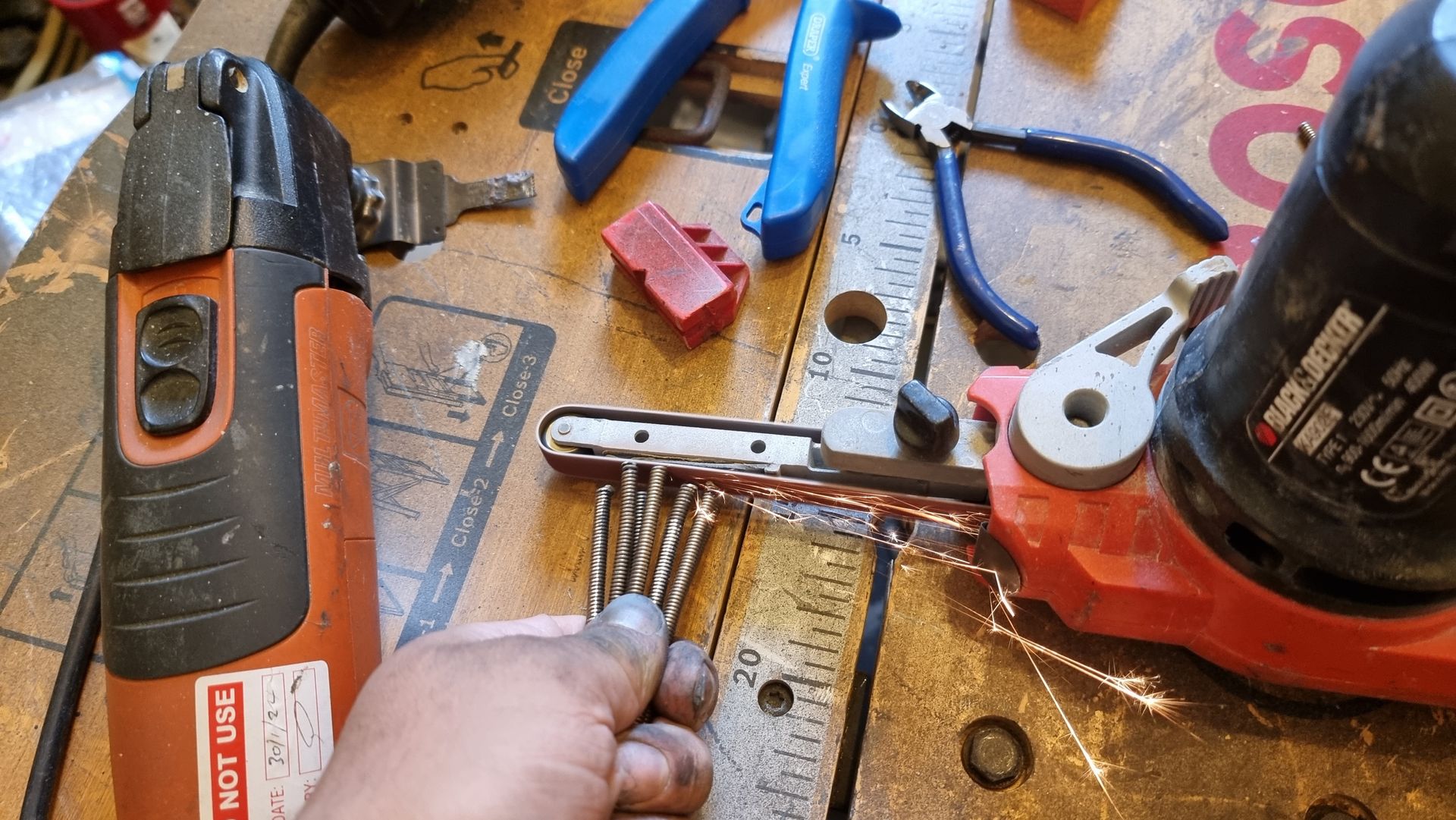

The only thing that worked was my angle grinder when the cable was held in the workbench and then right up against the vice in the table top.

The only thing that worked was my angle grinder when the cable was held in the workbench and then right up against the vice in the table top.

I then leveled and rounded them off with my powerful which worked better than the disc belt sander.

These were then painted as usual with the dirty down and metallic spray paints.

The original plan had been to permanently attach the cables to act as working supports but if I did that, I would not be able the unscrew the towers for safety in transport and storage.

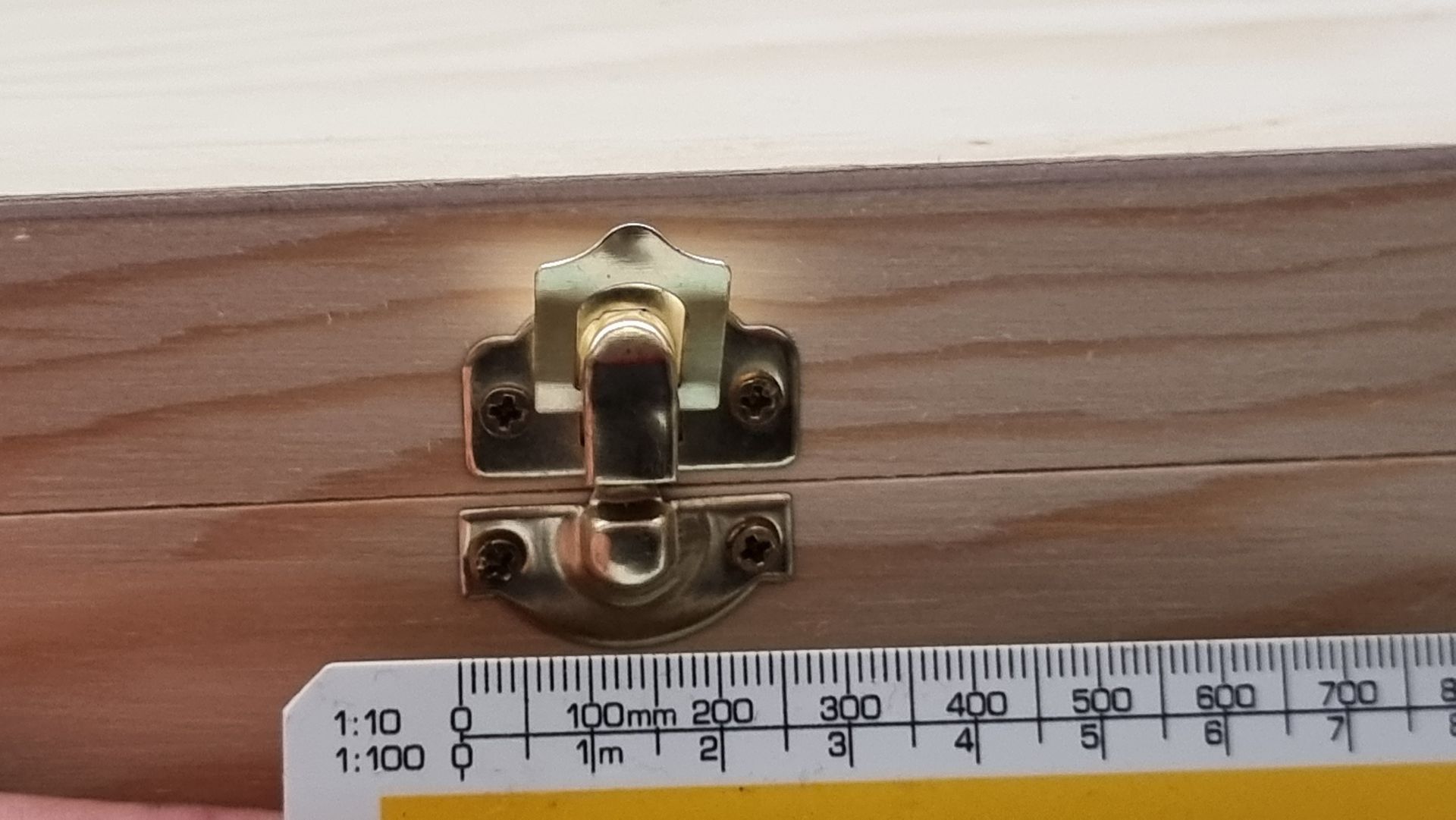

The base ends fitted nicely into the Nerf multi shot disc above the Dyson cyclone motors in the holes.

These where then glued into place with I think superglue and activator.

The other end just clipped securely into the doles on the tower component I think originated from a blow torch majorly enhancing he look.

Extending The Tower Support Cables March 2025

Problems to Solve

- It was found that the support cables were too short as can be seen from the first photos.

- This was much more apparent when twisting the handles added later to fit in the crate.

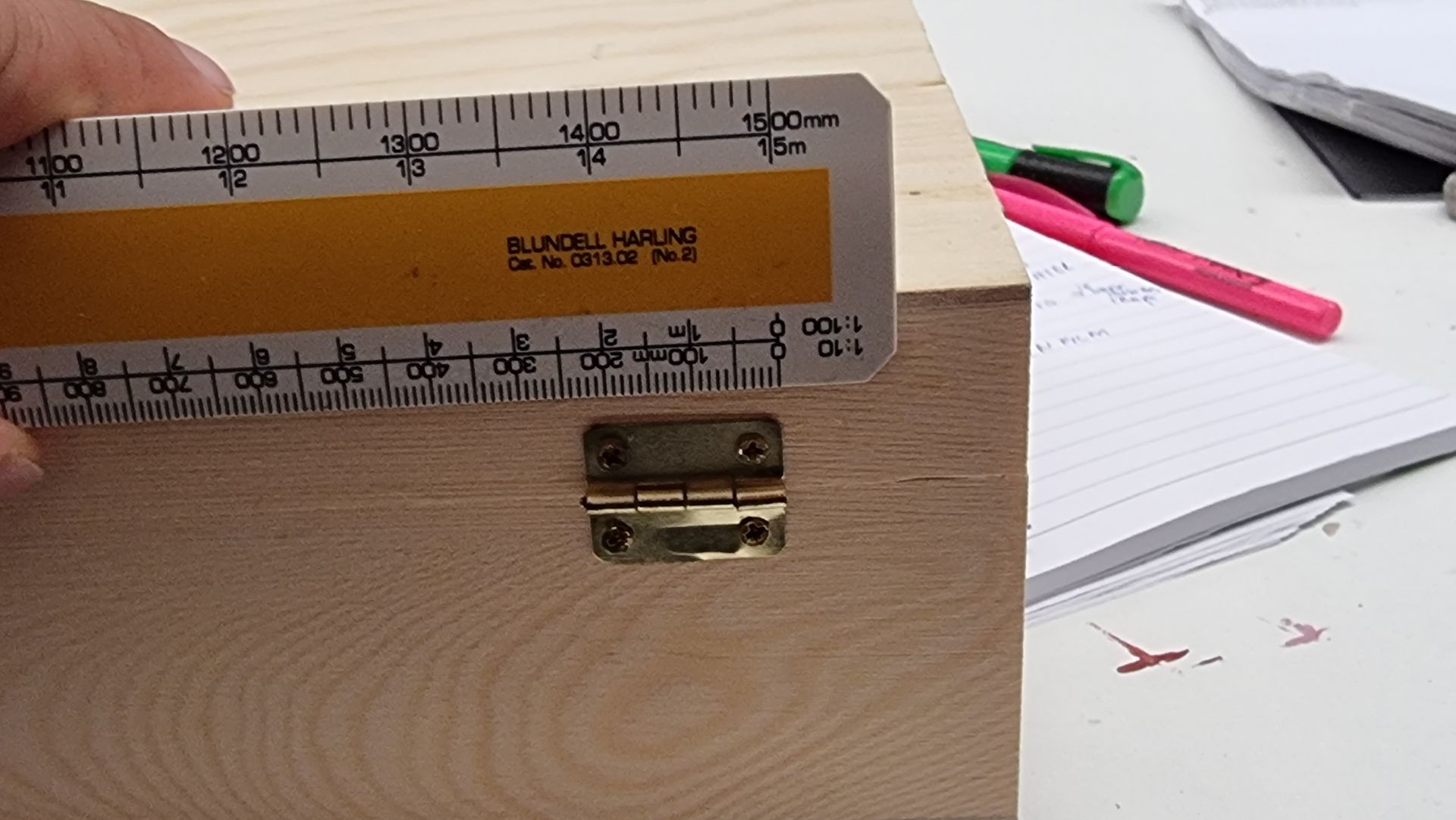

- I only needed and extra 10 - 15 mm but the issue was how.

- The cables were just held on the coles on a cylindrical component that looked like it came from a blow torch.

- However point on the cables I needed the extension joint is where all the sheer stress was focused due to bending under tension so the bond has to be super strong and structured or it would just snap.

- None of the glue techniques would work.

- Attaching some form of tube over the end would looks bad and be very obvious.

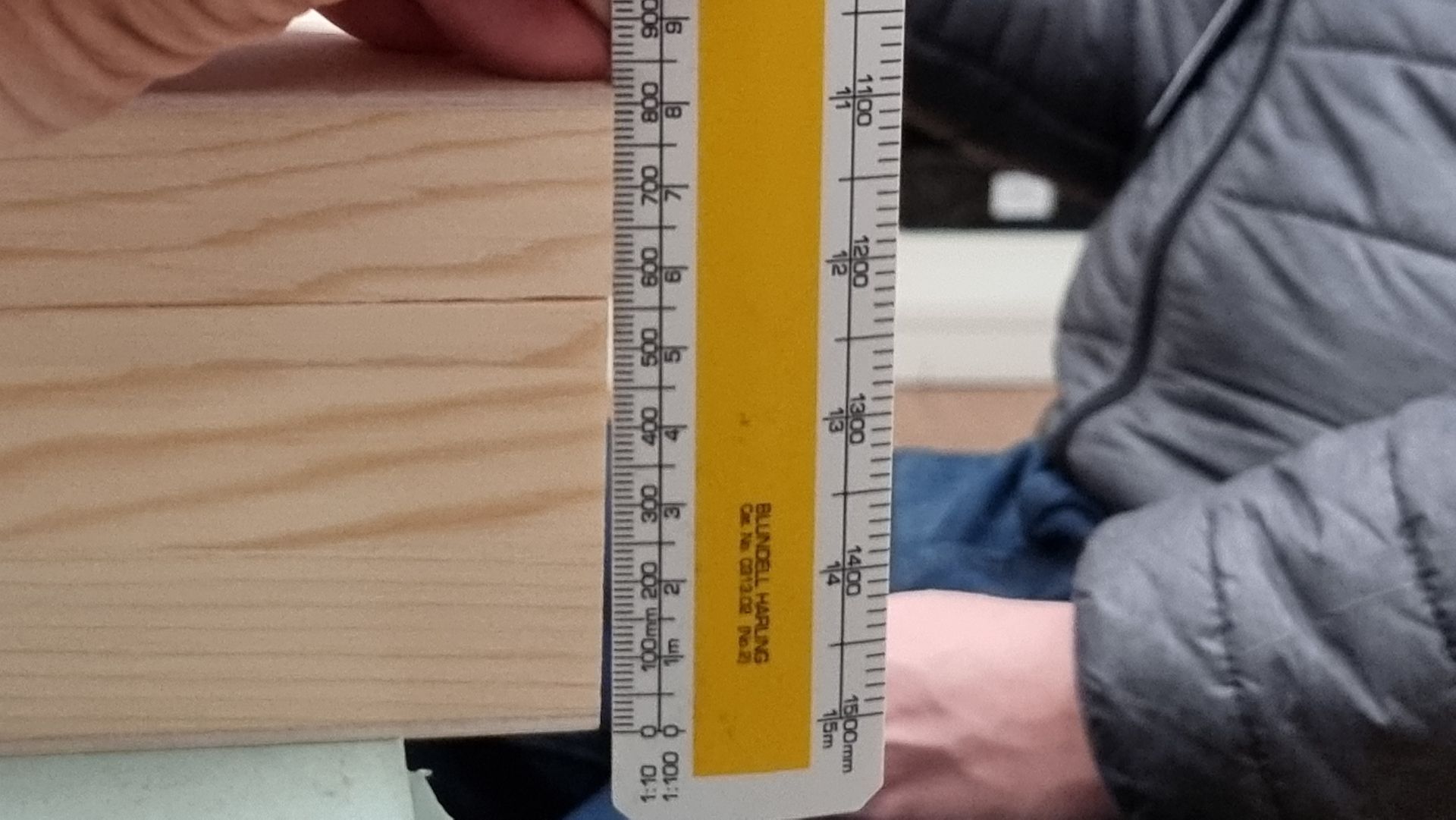

- As these were made from spring tubes (Drain cleaner rods.) that meant that they were hollow and flexible.

- Alao a major problem was their bottom ends where embedded in resin making them impossible to remove and replace without destroying the holding disc

Solutions

- To do this I needed very short lengths of the drain cleaning spring cable, only around 10mm.

- This was way to dangerous and impractical to cut with my mitre saw.

- I did try with an angle grinder but this gave a very rough messy cut.

- Thus, I moved to using my multi tool which gave a far cleaner cut.

- Thus, was not held well in the vice and prone to moving.

- I tried to fix this by encasing the spring cable in tissue.

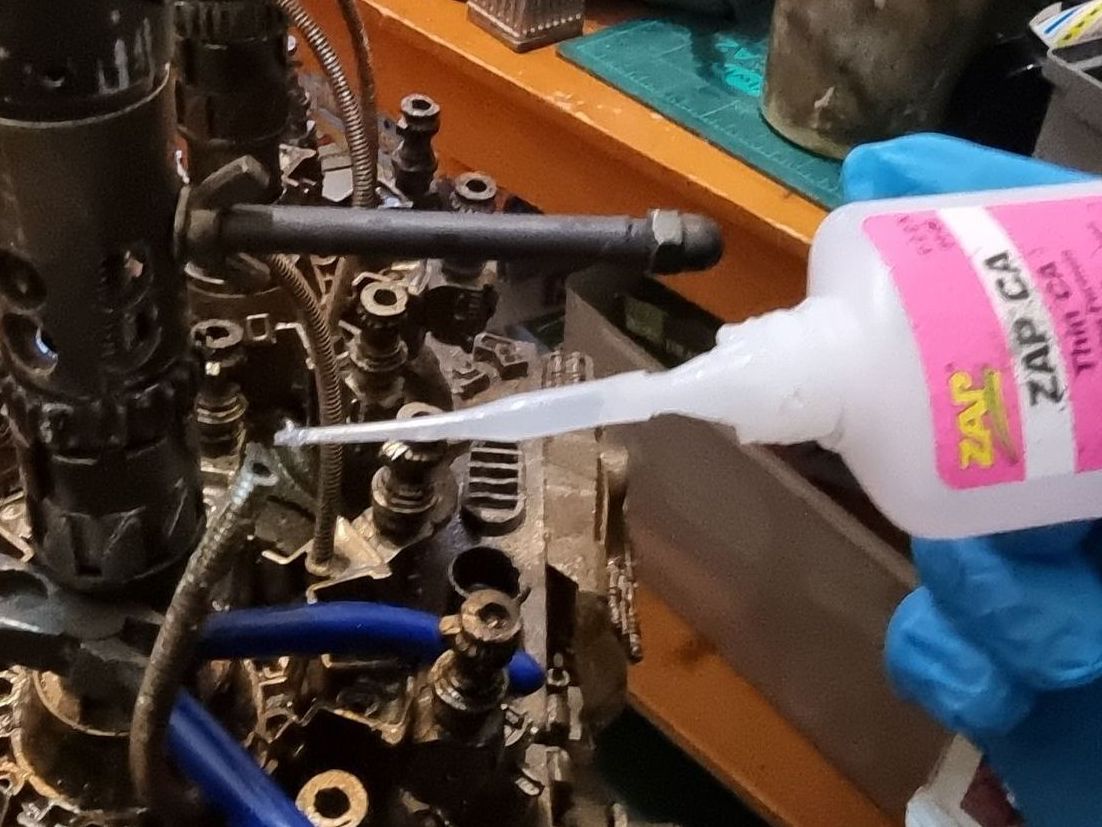

- Once I had the spring cable cut to length, I cut lengths of 3mm mild steel garden wire as a spine.

- These were about 3 cm long.

- This was inserted in the tubes to make a joint and then this was stuck with superglue.

- The result was a flexible strong extension joint.